Low-Volume Manufacturing Service

Yidian is recognized as an industry leader in providing the finest rapid low volume manufacturing services. Fortune 500 companies trust Yidian when they need production manufacturing solutions, uncompromising quality, and no minimum volume restrictions. Contact us for a free quotation to see how we can support your project.

What Is Low-Volume Manufacturing?

Low-volume manufacturing is a specialized service that offers full production-quality parts but in volumes ranging from a single piece to a few thousand pieces. It’s ideal for moving an idea from the concept stage through prototyping, and from there as a bridge to full volume production.

Low volume production is considered to be a specialized service because most manufacturers don’t want to do it. Their assembly lines and supply chains are optimized for large production volumes that leverage economies of scale. There is nothing wrong with that approach, because it’s the best way to ensure the lowest cost per piece. However, it usually requires large minimum order volumes and a commitment to expensive tooling.

But what is a product developer to do if you want to start off with product volumes on the low end, from one part to one thousand? That’s where Yidian help.

How To Process Low-Volume Manufacturing

What is the secret to low volume manufacturing success? Is there a difference in the types of raw materials that are used, the way that they’re processed, or the quality of the finished product?

Our clients are concerned that low-volume manufacturing doesn’t mean compromising quality or precision when compared to full production manufacturing. Rest assured that when we process lower volume orders we use the same materials, the same equipment, and the same rigorous quality control.

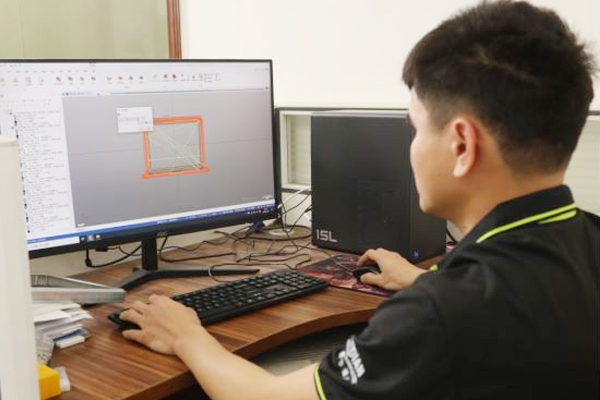

How do we do it? We’re experts in high-mix, low volume production because our systems are optimized to be scalable, from one part to a million. That means we have a robust supply chain of raw materials so you won’t be burdened with minimum order volume restrictions. And we have a digital manufacturing platform that ties all of our equipment together into a single network. That allows us to allocate resources quickly and efficiently between work centers in order to process even complex orders fast.

Not sure which low-volume manufacturing service is right for you? Here is more information about what we can offer.

Low-Volume Manufacturing Services

Yidian provides best-in-class low-volume manufacturing services. Learn how we can support you on your next project.

Rapid Prototyping

At Yidian, we specialize in the production of high-quality, low-cost prototypes.

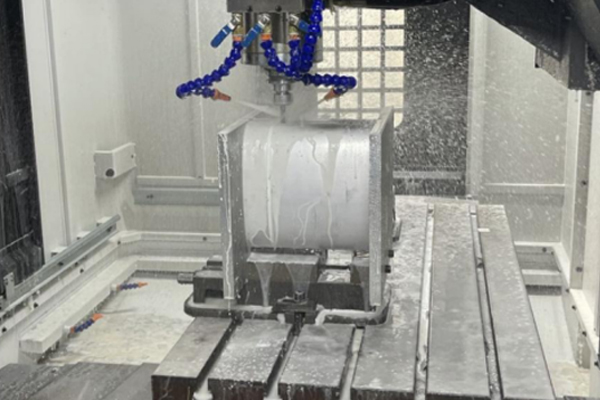

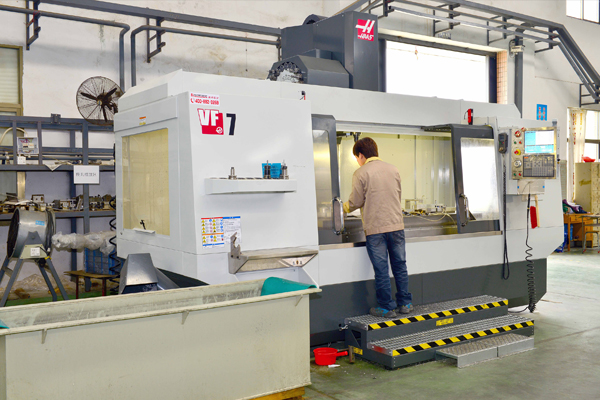

Learn moreCNC Machining

Using our imported 3, 4, and 5-axis CNC machining centers, our skilled machinists can make CNC milled and turned parts in a range of materials.

Aluminum Extrusion

Both fast and straightforward, aluminum extrusion yields products that are lightweight, strong and resistant to corrosion.

Learn moreSheet Metal Processing

Sheet metal processing speed, is not limited by the nature of materials, processing costs, rapid mass production, in the easy point sheet metal processing defect rate control at a very low level.

Learn moreAdvantages Of Low-Volume Manufacturing

How can low-volume manufacturing help you and your business? Here are a few ways:

- Create a bridge between rapid prototyping and full-scale production

- Reduce your financial risk because we have no minimum order values

- Provide rapid access to emerging markets

- Respond quickly to shorter product life cycles

- Allow for faster design changes

Yidian Low-Volume Production Service FAQS

What makes Yidian’s low-volume production service unique?

There are several factors that separate our low-volume production service from the competition. For one, we offer an extensive variety of complementary in-house services — including CNC machining, Aluminum Extrusion, and finishing — to deliver our clients comprehensive prototyping and NPI (new product introduction) solutions.

Secondly, we offer best-in-class material verification and testing services. Plus, we don’t require a minimum order volume or minimum dollar value, and we use state-of-the-art AI quotation algorithms for fast, accurate quotes.

Does Yidian manufacture the products?

Yes, our team completes all manufacturing at our facilities. This gives us a quality control advantage over other low-volume production services that outsource their manufacturing.

What materials does Yidian work with for its low-volume production service?

We routinely work with all conventional metals including copper, brass, stainless and mild steel, magnesium, and aluminum.

What are Yidian’s quality standards for low-volume production service?

The quality of your low-volume production parts is guaranteed by our rigorous control standards. This starts with an inspection of incoming materials to verify the integrity of all materials used. It also includes in-process inspection and testing to make sure you get parts that exceed your expectations. Certificates of Compliance are available upon request for all materials. For clients who can’t visit our facilities in person, we also offer detailed video files showing all production steps.

Why Choose Yidian for Low-Volume Production

✓ An Extensive Range of In-House Services

To meet the diverse low-volume production needs of our worldwide partners, our team proudly provides a wide range of in-house manufacturing services deployed with industry-leading agility. These include Rapid Prototyping, CNC machining, Aluminum Extrusion and more. You can trust us to manage your production with the precision and quality you deserve.

✓ A Proven Track Record

With centuries of combined experience, our engineers and technicians have helped thousands of organizations get their products off the ground. Keep reading to view our low-volume production projects.

✓

Industry-Leading Material Verification and Testing

Services

High-quality materials are the first step to top-notch products. We offer advanced incoming material inspection and verification to ensure that all raw materials will conform to your exact product specifications.

✓ Design for Manufacturing Support and Remote Flexibility

We provide detailed design for manufacturing support to our clients. For clients who can’t visit our facilities in person, we also offer detailed video files showing all production steps.

✓ Intelligent Quotations for Every Project

Low-volume production isn’t a one-size fits-all process. We never require a minimum order volume or minimum dollar value. We also use state-of-the-art AI quotation algorithms for fast, accurate quotes in 24-hours or less and in nearly all cases.

Yidian Low Volume Production Case Studies

Yidian specializes in low-volume production projects for various industries. Read our success stories.

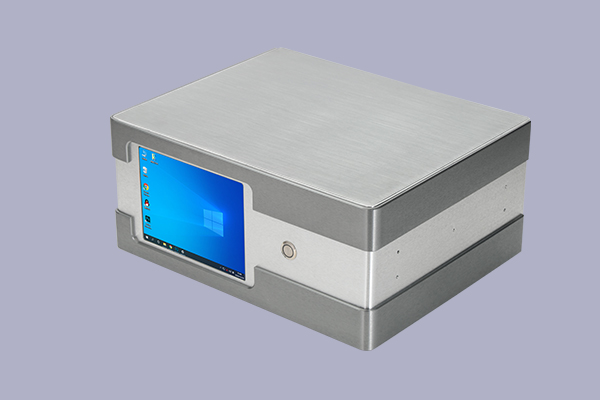

New energy shell with superior performance

New energy household energy storage battery ensures its strength and lightest weight at the same time. Life is waterproof, shockproof, wear-resistant and anti-aging.

Rapid response to a critical need

All metal CNC processing is very complex, and each process is very important. In CNC processing and secondary processing, carelessness may lead to the scrapping of the whole product. Secondary processing includes polishing, wire drawing, sand blasting, anodizing and other surface treatment processes. The cost of all metal CNC products has been very high when they are processed for the second time. If there are problems in these processes, such as a little scratch during wire drawing, it will take huge human and material resources to make up for them, and in many cases, they cannot be repaired, which has a great impact on the defect rate. Finally, our team solved the problem perfectly in the manufacturing process. The machining accuracy and defect rate were controlled within the range of 0.1%.

Sausage Vending Machine And Sofa Case Study

The sheet metal processing process uses laser cutting, numerical control bending, laser welding, simple forming, polishing and painting. Each link needs to strictly control the size and process. Through the efforts of easy point engineers, the expected effect of customers can be achieved perfectly.

Further Reading:

Low-Volume Manufacturing

Tips for Moving Your Product from Prototyping to Production

Many new product developers are able to design beautiful prototypes, but then struggle to convert those designs into successful commercial products. We’ve created this step-by-step guide to help make the transition easier and more successful. during the prototyping phase.

Top 7 Advantages to Using CNC Machining for Rapid Prototyping

CNC machining is one of the best ways to make rapid prototypes and low-volume finished parts quickly that are full strength and ready for immediate use. Learn all about the seven advantages of CNC machining for rapid prototyping.

Request Your Free Low-Volume Production Quote Today

Our improved algorithm decreases low-volume manufacturing quotation times by up to 90%. Most quotes are delivered within 24-hours, or less, depending on the project details. Your customer support partner will contact you directly to ensure that you’ve received and understand all aspects of your quotation and to answer any questions you may have!