What Can Yidian’s Finishing Services Do For You?

Your parts aren’t really complete until they’ve gone through our professional finishing department. Whether in metal or plastic, from a one-off prototype to full mass production, we have everything you need to take your project that final step to perfection.

A Full Suite of Professional Finishing Services

We don’t just make parts. We make them better by applying a variety of treatments to improve their appearance, performance and durability. Learn more about our major finishing services.

- Anodizing

- Painting

- Color Matching

- Pad and Silk Screen Printing

- Sanding and Polishing

- Polishing

- Blasting

- Wire Drawing

- Electroplate

- Spray

- Dusting

Anodizing

Yidian is an expert on anodizing aluminum, magnesium or titanium. Anodizing helps to resist corrosion, increase surface hardness, improve resistance to wear and dissipate heat. It’s also an ideal surface treatment for painting and priming, and it looks great too.

We normally use Type II anodizing, which allows us to add tints or dyes to your parts to enhance their looks. Type III is also available for surfaces that need to be extra hard.

Anodizing Aluminum And Titanium

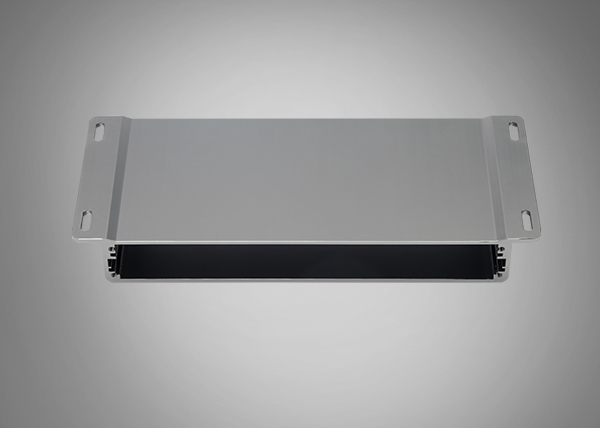

Painting

A great paint job is one of the best ways to make your product stand out from the crowd. Using only the finest PPG automotive polyurethanes, we can replicate virtually any color, tint or hue in our climate-controlled, automated spray room. Our master painters can supply millions of colors, in matte, flat, semi-gloss or glossy finishes.

Soft-Touch Painting

You can also have a soft-touch paint coating on almost any surface, either plastic or metal. This type of paint gives a matte-finished, non-slip texture that also blocks glare and hides fingerprints. It’s common on hand-held controllers and front panels on consumer goods that get touched a lot.

The coating is clear and so it won’t change the color of the base material. Product developers should note that soft coatings are not a substitute for actual rubber or elastomer overmoldings, which are much more durable.

Painting at Yidian

High Gloss And Matte Paints

Soft Touch Paint

Texture Paint

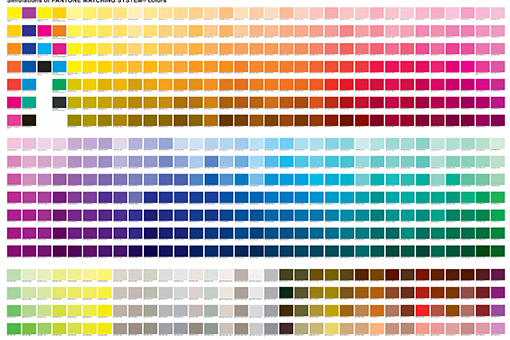

Color Matching

Getting a perfect color match can be tricky. That’s why we use advanced color spectrophotometers to make precise measurements of surface color, tint and reflectance. This helps us to match your color samples, and to ensure that we apply Pantone or other RGB colors exactly to your specifications.

Pad Printing

Many products require a company’s brand name or logo printed on the surface. How is this done? One way is to use pad printing. Your desired image is embossed onto a hard rubber block.This becomes a stamp that we use to imprint simple words and graphics on flat or slightly curved surfaces. Pad printing is very inexpensive and fast. Pad printing is limited, however, to a single color at a time.

Silk Screen Printing

What if you need more color options, or you have a complex graphic you want to apply? Silk screen printing may be the answer. It involves using a fine mesh screen that’s partially covered by a stencil of the desired pattern. For more complicated images or multiple colors, several different screens and stencils are used in series.

Paint is then squeezed through the mesh and onto the surface of the substrate in every location that’s not blocked by the stencil. With careful choreography it’s possible to make sophisticated multi-colored images, text and colored patterns on almost any hard flat surface. Silk screen printing is inexpensive, versatile, and stencils can be made quickly. Is it right for your project? Contact us to learn more.

Pad Printing In Custom Colors

Sanding And Polishing

Sanding is not just used for painting preparation but also to create the final surface effect. We can provide brushed and satin surfaces on metal, and we make optically clear polishes on transparent plastic. Hand sanding is also a very important part of the vacuum casting process, because master patterns must be carefully prepared before copies can be made.

Aluminum Sanding

ABS Sanding

PMMA Polishing

Aluminum Polishing

Polishing

Polishing refers to the processing method of using mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece in order to obtain a bright and flat surface. It refers to the modification of the workpiece surface with polishing tools, abrasive particles or other polishing media.

Polishing at Yidian

Polishing

High Gloss Edge

Five Axis Highlight Machine

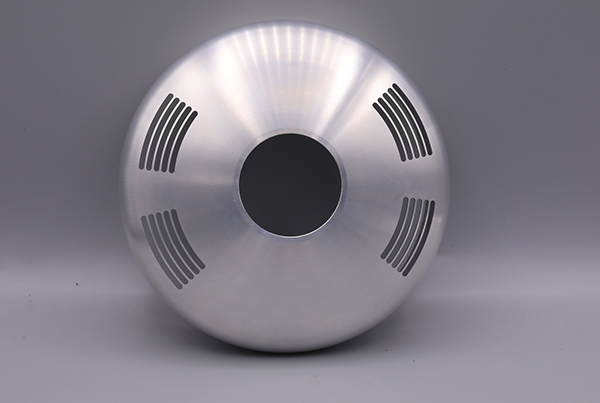

Blasting

The sand blasting adopts compressed air as the power to form a high-speed jet beam to spray the sprayed materials (copper ore, quartz sand, carborundum, iron sand and sea sand) to the workpiece surface to be treated at high speed, so as to change the appearance or shape of the workpiece surface. Due to the impact and cutting effect of abrasive on the workpiece surface, the workpiece surface can obtain certain cleanliness and different roughness, and the mechanical properties of the workpiece surface can be improved. Therefore, it improves the fatigue resistance of the workpiece, increases the adhesion between it and the coating, prolongs the durability of the coating film, and is also conducive to the leveling and decoration of the coating. Sand blasting is the most thorough, universal, rapid and efficient cleaning method. Sandblasting methods include: Press in sandblasting and suction sandblasting, dry sandblasting and liquid sandblasting, open sandblasting and box (room) sandblasting.

Sand Blast Finish

Wire drawing

Wire drawing treatment is to form lines on the surface of the workpiece by grinding products. According to different surface effects, it is usually divided into straight wires and tangled wires. The effect of wire drawing lines is determined by determining the processing mode of wire drawing, grinding products used, process parameters and so on.

According to the requirements of wire drawing effect and the size and shape of different workpiece surfaces, different processing methods are selected. There are two kinds of wire drawing methods: manual wire drawing and mechanical wire drawing. Mechanical wire drawing includes: flat pressing abrasive belt wire drawing, non-woven roller brush wire drawing, wide abrasive belt wire drawing, centerless grinding wire drawing, polishing machine wire drawing, etc.

Wire Drawing Finish

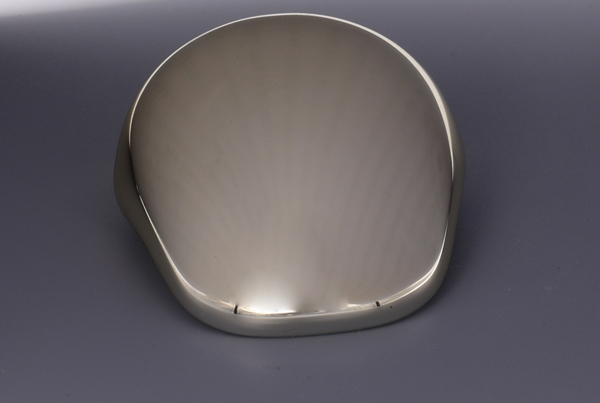

Electroplate

Electroplating is a process of plating a thin layer of other metals or alloys on some metal surfaces by using the principle of electrolysis. It is a process of using electrolysis to attach a metal film to the surface of metal or other material parts, so as to prevent metal oxidation (such as rust), improve wear resistance, conductivity, reflection, corrosion resistance (copper sulfate, etc.) and enhance beauty. Electroplating is divided into hanging plating, barrel plating, continuous plating and brush plating, which is mainly related to the size and batch of parts to be plated. Yidian supports electroplating methods such as single metal coating, alloy coating and composite coating.

Electroplate Finish

Spray

Spraying is a coating method that disperses into uniform and fine droplets through a spray gun or disc atomizer with the help of pressure or centrifugal force and is applied to the surface of the coated object. It can be divided into air spraying, airless spraying, electrostatic spraying and various derived methods of the above basic spraying forms, such as high flow and low pressure atomization spraying, thermal spraying, automatic spraying, multi-group spraying, etc. at present, there are four main spraying technologies: arc spraying, flame spraying, plasma spraying and explosive spraying. Using spraying technology, coatings with wear resistance, corrosion resistance, heat insulation, conductivity, insulation, sealing, lubrication and other special mechanical physical and chemical properties can be obtained on various substrates. It has a wide range of applications, involving all sectors of the national economy and various fields including cutting-edge technology.

Spray Finish

Powder Spraying

Powder spraying refers to a coating process in which powder coatings are adhered to the workpiece by corona discharge. After powder spraying, it was successfully coated by heat. In 1962, France's semes company invented powder electrostatic spraying, and powder coating began. Powder coating has been used in protection and electrical edge. With the development of science and technology, it has been widely used in the coating of automotive industry, electrical insulation, corrosion-resistant chemical pumps, valves, cylinders, pipelines, outdoor steel components, steel furniture, castings and other surfaces.

Powder Spraying Finish

Get Your Project Started Today

Still haven’t found the type of finish you want? If you have any other special requirements we pride ourselves on finding solutions for any of your custom needs. Contact us today for a free quote to get your next project started.