CNC Machining Services

Bespoke manufacturing services of CNC machined parts,

from one-off prototypes to full mass production.

Request a CNC machining quote today.

Request a QuoteCNC Machining Services

Yidian’s CNC machining services offer you precision fabrication of plastic and metal parts in any volume. We specialize in multi-axis milling, turning, EDM, surface grinding, laser engraving and much more. In addition, you’re assured that all raw materials will meet your exact specifications because of our best-in-class testing and verification laboratory. That’s one of many reasons why we are a preferred supplier to world-class companies for their most demanding CNC machining projects.

CNC Machining – What Is It and Why Do You Need It?

CNC machining is a broad manufacturing category that includes many different computer-controlled processes where raw material is selectively removed in exact amounts to produce a near-final shape of parts. That’s why it’s considered subtractive, as opposed to additive manufacturing or 3D printing. Standard CNC machining processes include milling, turning, surface grinding and electrical discharge machining (EDM) although there are other specialized applications. Whenever a machine is digitally controlled there must always be a 3D CAD file of the part design which is used to program the machine’s movements.

CNC machining is used on many common metals such as aluminum, brass, mild and stainless steels, magnesium and titanium. It can also be used on rigid or engineering-grade plastic resins. We employ it every day to make not only finished parts but also tools and dies that are used for plastic injection molding and pressure die casting.

Because of the reliability and precision afforded by modern tools controlled with sophisticated software, CNC machining is an ideal rapid prototyping and production volume solution for making complex end-use parts with very tight tolerances.

One of the great advantages to CNC machining is its versatility. It is highly flexible and adaptable to many shapes and sizes of parts, and because there is no need for fixed tooling one part can be made just as easily as one thousand. CNC machined components are full strength and they have excellent surface finishes. You can choose to put them into service immediately or they can be further processed with additional treatments such as plating, polishing, anodizing, painting and more.

CNC Machining Video | Yidian

CNC Machining Raw Materials

We work with a wide range of metal alloy materials including magnesium, mild and stainless steel, aluminum, brass. These materials are part of our standard inventory and can be sourced for immediate availability from reliable vendors who have been thoroughly vetted and approved by us. In addition we can also provide specialty materials such as super hard alloys – just talk with our engineers to learn how we can meet your needs.

Most importantly, to ensure that your CNC machined parts meet all regulatory requirements we have an incoming materials inspection lab where we use sophisticated analytic testing instruments using Raman spectroscopy to confirm the exact chemical and physical properties of all raw materials. We leave nothing to chance for your peace of mind.

Our CNC Services

Yidian provides custom CNC milling and lathe services. Learn more about what services we offer.

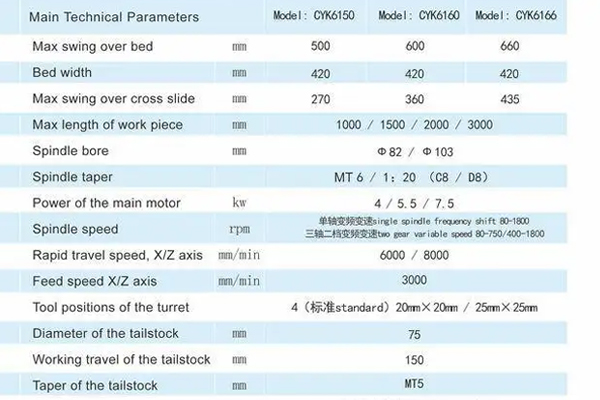

CNC Turning Services

CNC turning is the ideal way to make deep holes, machined threads, and all types of cylindrical shapes that have superior surface finishes. When you need precisely manufactured parts, fast turnaround, and no volume limitations, CNC turning at Yidian is your solution. Learn more about how we can support you.

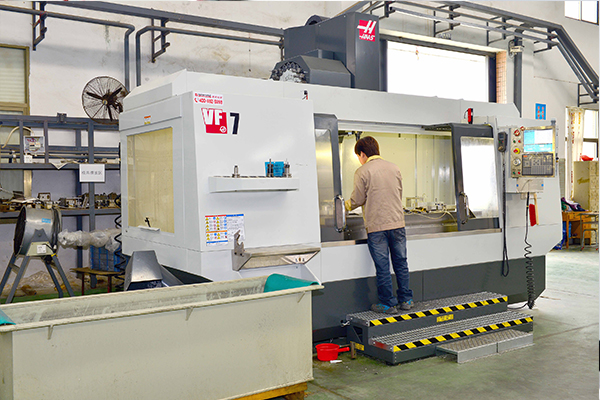

CNC Milling Services

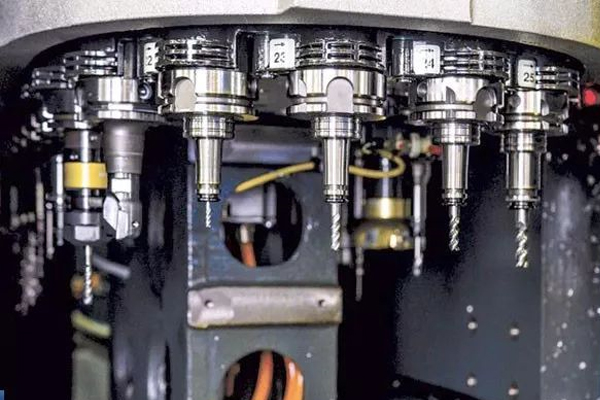

CNC milling makes complex prismatic shapes and flat surfaces for a limitless variety of commercial and industrial products. Multi-axis metal CNC machines require no fixed tooling, are highly flexible, and extremely accurate. Learn more about how we can support your most demanding CNC milling projects with no volume limitations.

EDM Services

Electrical discharge machining (EDM) is a specialized form of CNC machining. Controlled pulses of electricity are used to erode even the hardest metals with great precision. This is essential when machining hardened tool steels. When done correctly, the surface finish is mirror-smooth and requires no secondary polishing.

Surface Grinding

If you need an extremely flat surface on your parts, there is no better way than by surface grinding. In this precision CNC machining service, a special abrasive wheel passes over the face of the workpiece, carefully controlled by digital motors, to provide the ultimate in surface flatness. Contact us to learn more about how it can help you.

CNC Machining

Tolerances

Our general tolerance for machined parts in metal is DIN-2768-1-fine. For our plastic CNC service, we work to the DIN-2768-1-medium standard. Since tolerances and dimensions can be greatly affected by the part’s geometry and the type of material, we highly recommend consulting with our engineers in advance if you have any concerns.

Rapid Tooling Services

CNC manufacturing is used for more than just finished parts. When you need high-quality Aluminum Extrusion tools made quickly, we offer custom CNC machining services for rapid tools, prototypes, and low-volume production. Along with the rest of our manufacturing services, it’s another way to help bring your product ideas to life quickly and with total quality assurance.

Yidian CNC Machining Service FAQ

Why choose CNC machining?

CNC machining is fast, accurate, and versatile. No other manufacturing solution produces end-use parts in any volume without the need to invest in hard tooling or expensive set-ups.

What raw materials can I use with CNC machining?

Almost any rigid solid can be machined, including mild and stainless steels, aluminum, brass, copper, magnesium, titanium, and many types of engineering plastics. Check out our list of frequently used materials.

What tolerances can I achieve with CNC machining?

Our standard tolerances are 0.05 microns, which is suitable for the majority of commercial and industrial applications. Consult with us if you need closer tolerances for special projects.

Why Choose Yidian For CNC Machining Services

Yidian’s CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

✓ Industry-Leading CNC machining equipment

Imported 5-axis CNC machining centers running the most advanced AutoDesk and Vericut software. Exclusive Guhring cutting tools from Germany for the finest tool performance and longevity.

✓ Intelligent pricing for every CNC machining project

Offering you a proprietary, patent-pending AI quotation algorithm. The power of machine learning gives you fast and accurate CNC machining quotes without guesswork.

✓ Comprehensive raw material testing and verification

No one in the industry offers more dependable positive material identification (PMI). You can proceed with full confidence that your parts will meet all of your material specifications and regulatory compliance requirements.

✓ A full suite of finishing services

Most CNC machined parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Advantages Of CNC Machining Services

One of the great advantages of CNC machining is that it works so well with so many different materials. These include mild and stainless steels, magnesium, brass, titanium, and even very hard alloys such as Inconel. In addition, rigid engineering plastics can be machined, as well as carbon fiber. All of these options give you even more design freedom. Learn more about our standard materials.

No matter what material you use, you need absolute confidence that it conforms to your specifications and regulatory requirements. That’s why we have a best-in-class material testing laboratory. We use positive material identification (PMI) to verify all incoming stock, and provide you with a full physical analysis. It’s the only way to be sure you get exactly the quality and performance you demand.

CNC machining offers many advantages for product developers, including

- Fast material removal

- Tight tolerances and high precision

- Excellent for making complex geometries

- Versatile

- Suitable for many different kinds of substrates

- Unlimited volumes

- Low investment in tooling

- Fast turnaround

- Parts are full-strength

- Excellent surface finishes

- Easily customized

Yidian’s CNC Machining Projects

Intelligent Anti-theft Door

The deer uses CNC precision machining, and the surface finish is required to reach 0.1. After treatment, it is manually polished 8K and oxidized bronze. In many processes, each link must reach the expected processing value in order to better meet the needs of customers. The ring handle is also precision machined by CNC, with a surface finish of 0.1. Manual arc wire drawing. We use the rotating disc to achieve the wire drawing effect required by customers.

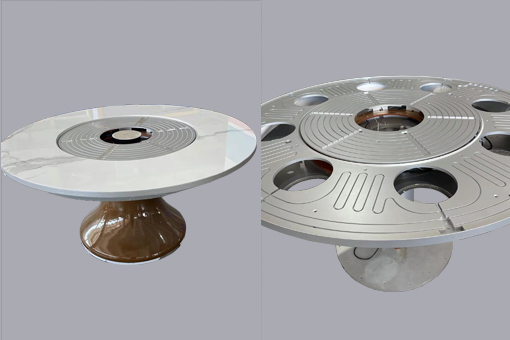

Smart Dning Table

The diameter of the smart dining table reaches 1600mm. We use large CNC to process it, and the assembly accuracy is controlled at 0.15mm. There are 38 assembly parts, and the assembly tolerance of each part is controlled at 0.15mm. Finally, it is perfectly solved by the technical team.

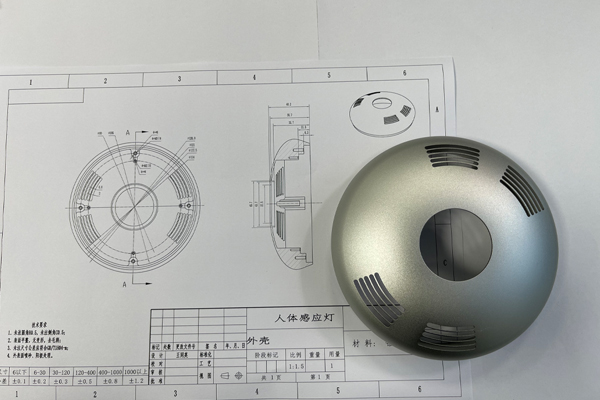

Lighting Trim

This part is precision machined by 5-axis CNC to perfectly control the size and surface roughness. For surface polishing, we use experienced polishing engineers to control the surface arc and the design tolerance of the original drawing within 0.1mm, and then electroplate 8K mirror effect.

Smart Speech Box

This product passes through CNC turning and CNC milling machine. In this processing process, we also encounter high requirements for machining accuracy and surface. And plastic parts, and finally solve the assembly problem of plastic parts and metal parts.

CNC Machining: Further Reading

Improving CNC Machined Parts With Thin Film Coatings

Yidian exclusively uses Gühring end mills and cutters from Germany. An industry leader, Gühring applies special thin film coatings to their tools. These coatings increase tear and heat resistance, improve lubrication and tool hardness. For product developers this means less machine downtime, faster cutting speeds and superior surface finishes. Read more about why we use Gühring tools for our CNC machining services.

How To Choose The Right Material For CNC Machining

What is the right CNC machining material for you? To help you find the best solution for your needs, we’ve put together this guide on the advantages and applications of the most common materials we use every day to make prototypes and production parts.

Read moreRequest Your Free CNC Machining Quote Today

Our improved algorithm decreases CNC machining quotation times by up to 90%. Most quotes are delivered within 24 hrs., depending on project details. Your customer support partner will contact you directly about your CNC machining quote to ensure you’ve received it and to answer any questions you may have about your options.