Sheet Metal Processing Service

Yidian provides a full range of sheet metal processing services. These include mold manufacturing, CNC stamping, Laser cutting, Laser welding, CNC bending, Powder spraying, Painting, Polishing, Plectroplating, etc. Our advanced inspection and testing equipment can ensure the quality of your raw materials and finished parts. When you send us CAD or 3D files to get a free quotation, we invite you to experience our professional services at an unparalleled price.

What Is Sheet Metal Processing?

Sheet metal processing includes traditional cutting and blanking, blanking, bending forming and other methods and process parameters, as well as various cold stamping die structures and process parameters, various equipment working principles and operation methods, as well as new stamping technology and new process. Part sheet metal processing is called sheet metal processing.

Advantages Of Sheet Metal Processing

- Machinable metals include aluminum plate, steel plate and stainless steel plate

- Mold tools can economically manufacture tens of thousands of parts

- Fast forming speed and small batch production

- Complex geometries can be achieved

- It is especially suitable for the shell of machinery and equipment

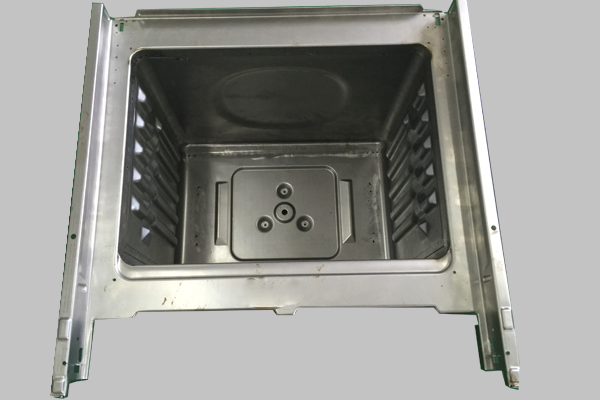

Sheet Metal Processing

Enquire About Sheet Metal Processing

Do not hesitate to contact us for more information about Sheet Metal Processing. Your customer support partner

will contact you directly to answer any questions you may have.

When to Use Sheet Metal Processing?

Sheet metal processing is used to manufacture household decoration products, as well as precision parts such as electronic appliances, communication equipment, automobile shell and fuselage. In addition, it is also applicable to the manufacture of medical devices.

Materials

The Sheet Metal Processing materials that we use at Yidian are Aluminum plate, aluminum alloy plate, stainless steel plate, cold rolled steel plate, hot galvanized steel plate, hot rolled steel plate, copper plate, etc They have their own characteristics and meet the needs of most projects.

Why Choose Yidian for Sheet Metal Processing Services?

Need to copy your metal products? Sheet metal processing is your solution. At Yidian, we are in a leading position in the industry in terms of efficient and high-quality processing services, which can be applied to any organization. Here are several reasons why thousands of enterprises around the world choose us for processing.

✓ Services That Go the Extra Step

Our internal services play an important role in distinguishing our processed parts from our competitors. We carry out all CNC processing in-house and provide extensive engineering support to customers when needed.

✓ Extensive Material Testing and Supervision

In order to ensure the highest quality level from beginning to end, we have conducted an extensive verification process for all raw materials used in processing services. We also provide 100% supervision for all sheet metal processing.

✓ Intelligent and Competitive Pricing

Our sheet metal processing service is one of the most affordable services in the industry, and the price is usually lower than that of most manufacturers in the United States, the European Union and Australia. In order to eliminate trouble, we never ask for a minimum order quantity or a minimum dollar value. In addition, for almost all projects, we use the most advanced AI quotation algorithm to quickly provide you with quotations in 24 hours or less.

✓ Industry-Leading Experience and Equipment

Our team has hundreds of years of comprehensive experience in the manufacturing industry. We have worked with a variety of customers to develop an incredible range of products.

✓ IProven Results

Our sheet metal processing services have helped countless organizations in many industries develop life changing products. Browse the "view our past projects" section of this page to read some of our many success stories.

Enquire About Sheet Metal Processing

Do not hesitate to contact us for more information about Sheet Metal Processing. Your customer support partner

will contact you directly to answer any questions you may have.

See Our Past Projects

Sausage Vending Machine And Sofa Case Study

The sheet metal processing process uses laser cutting, numerical control bending, laser welding, simple forming, polishing and painting. Each link needs to strictly control the size and process. Through the efforts of easy point engineers, the expected effect of customers can be achieved perfectly.

Sheet Metal Processing Process

The success of your sheet metal processing project depends on advanced production equipment and high-quality talents, and our sheet metal processing and manufacturing capacity is unparalleled in Asia. Upon receipt of your order, we will:

Sheet Metal Processing Tolerances

The final dimension and surface requirements of sheet metal processing parts should be analyzed and communicated in detail according to your requirements to meet your needs. See tolerance list for details.

Yidian Sheet Metal Processing Service FAQ

What makes Yidian’s Sheet Metal Processing service unique?

Our Sheet Metal Processing service is noted for its exceptional quality and speed. Our skilled technicians combine decades of experience with the latest technologies to produce exceptional prototypes and engineering models quickly. We can also further enhance your parts with a suite of finishing services including machining, media blasting, printing, painting and more.

Can Yidian provide design services, industrial design support or product development support as an extension of its Sheet Metal Processing services?

Yes. To supplement our Sheet Metal Processing services, we offer an expanded service geared for design-for-manufacturing support. While we once reserved this service only for approved orders, we now provide it to all incoming RFQs. We also offer light assembly services to meet your needs.

What are Yidian’s quality standards for its Sheet Metal Processing services?

To ensure the highest standard of quality for all of your finished parts, our team adheres to a strict quality control process. This starts with the verification and testing of all materials. During production, we meticulously control temperature, humidity and other processing conditions to maintain the highest degree of consistency in your parts.

How do I get a quote for Yidian’s Sheet Metal Processing services?

We make it easy to get a fast quotation. Simply upload your CAD files and product details and we’ll send you a free quotation within 24 hrs. or less.

Request Your Free Sheet Metal Processing Quote Today

Our improved algorithm decreases Sheet Metal Processing quotation times by up to 90%. Most quotes are delivered within 24 hrs. and usually much less, depending on project details.

Your customer support partner will contact you directly to ensure you’ve received and understand all aspects of your quotation and to answer any questions you may have.